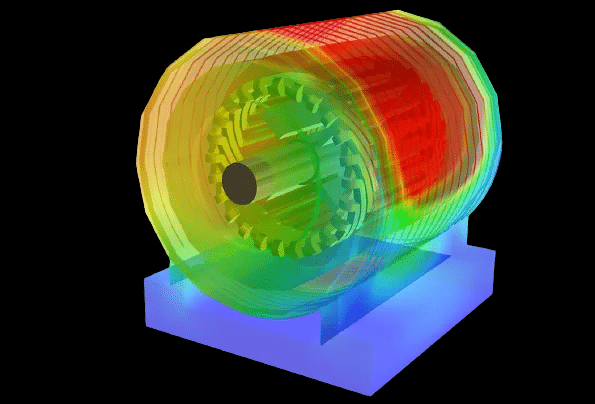

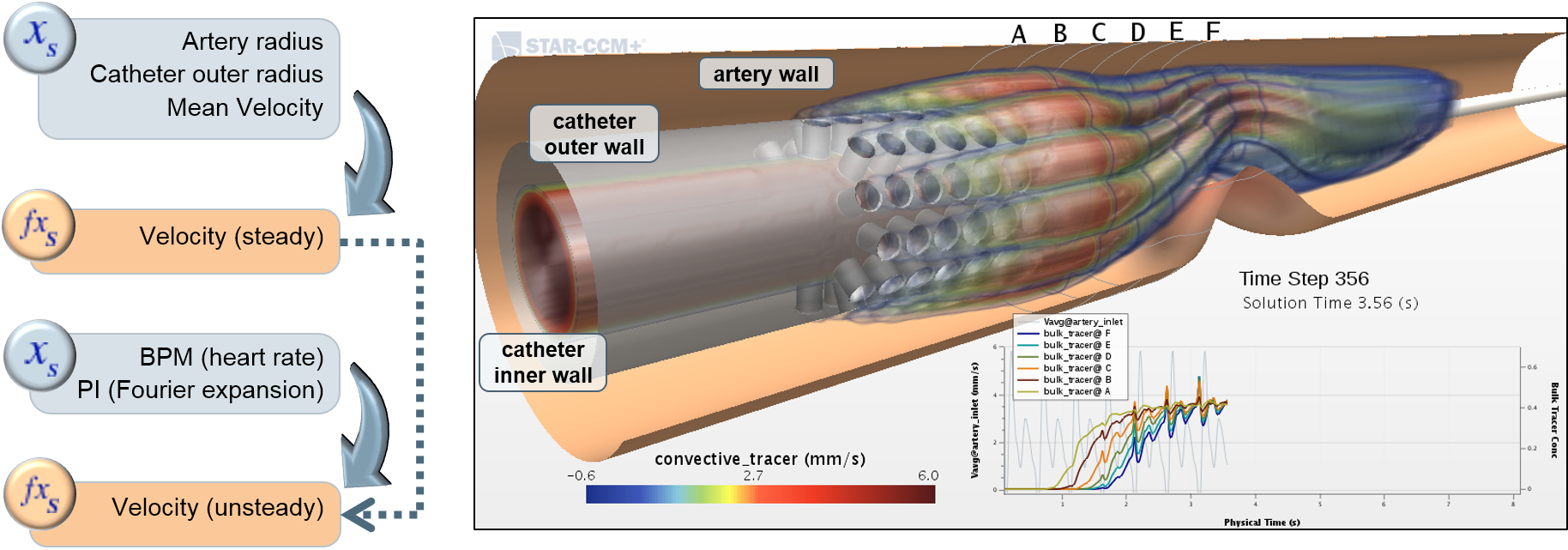

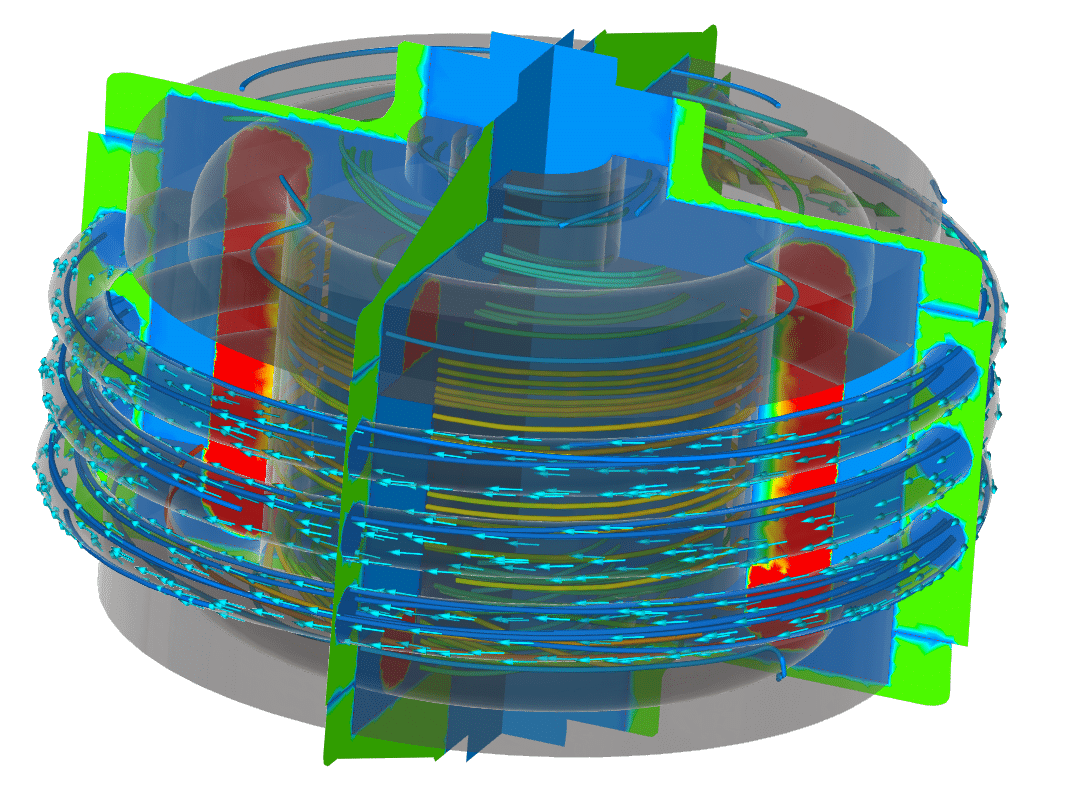

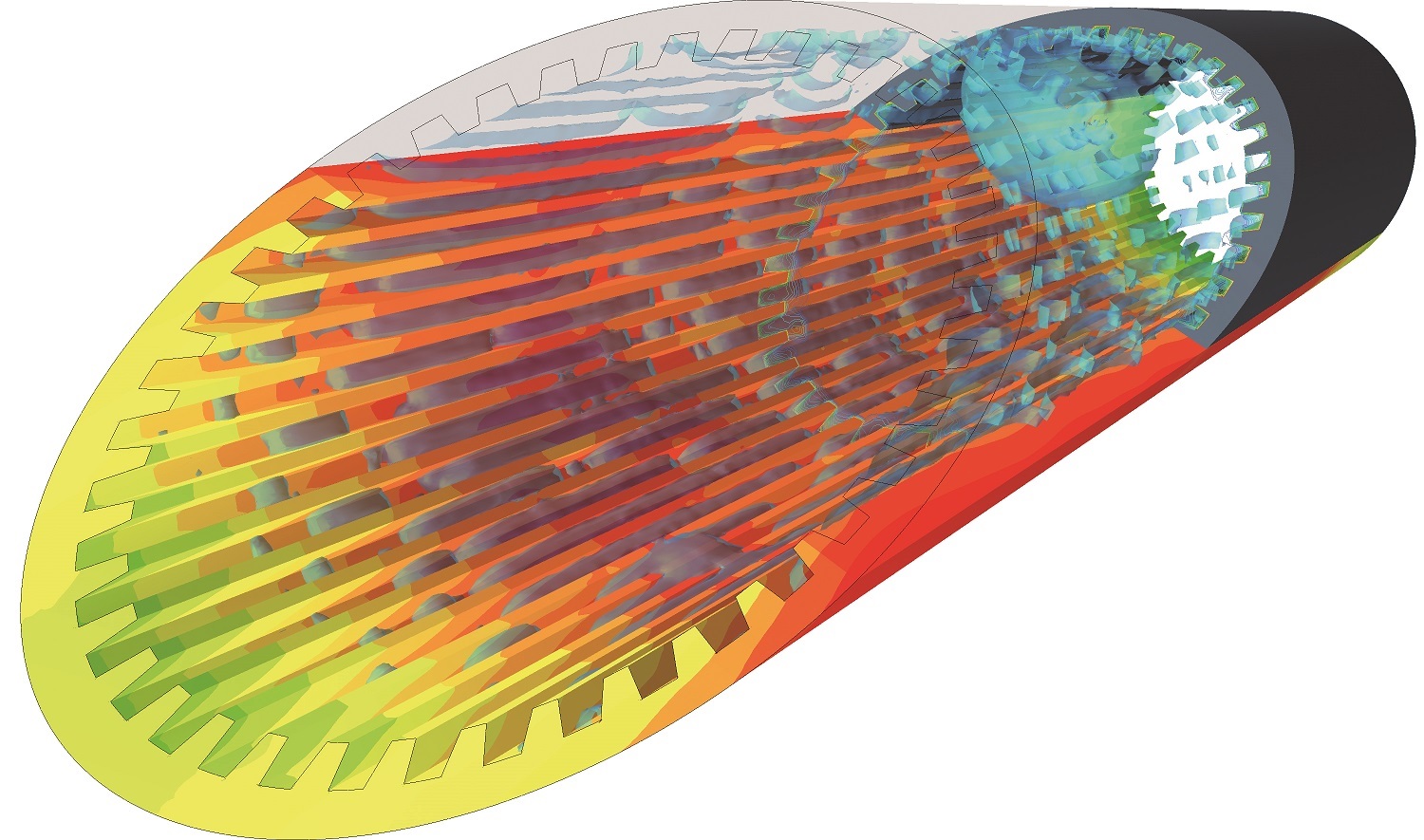

Solving thermal problems with CHT limits the engineer to the physical models that are contained within the CFD solver. More complex problems, such as those involving multimaterial structures or more accurate heat transfer coefficient (HTC) boundary conditions, can be solved by linking the CFD solver to a structural solver.

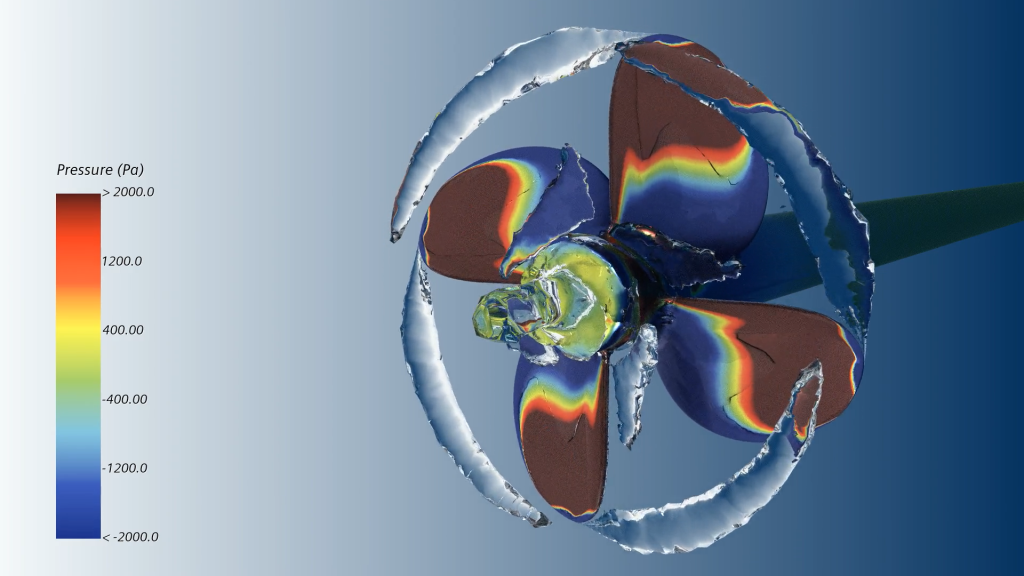

Transferring solid temperature fields from CFD CHT simulations to a structural thermal system makes it possible to take advantage of FSI simulation. The temperatures or HTCs calculated by CFD — and, if desired, the surface loads — are transferred to the structural finite element analysis (FEA) code. The FEA code then calculates the heat transfer and thermal fields in the structure as well as thermal–mechanical stresses.

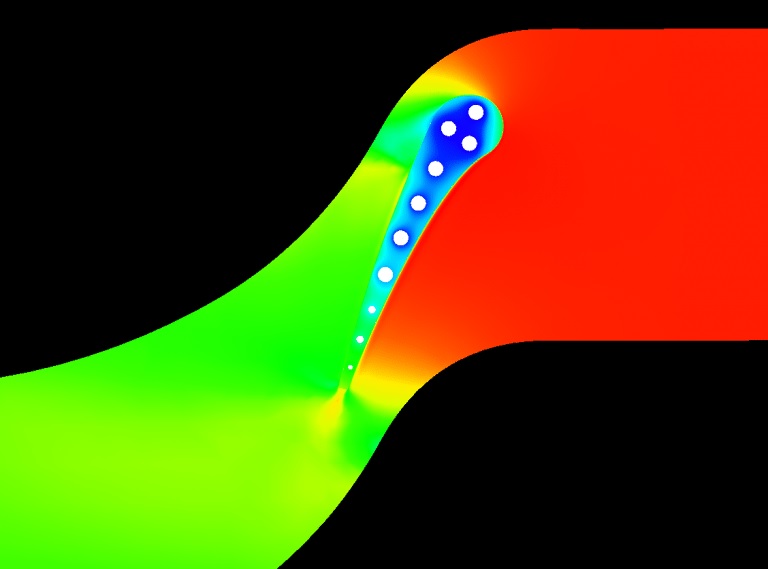

A characteristic of a one-way fluid–structure interaction (FSI) solution is that the stresses and deformations calculated in the structural solver are not passed back to CFD to update the mesh and recalculate the flow.

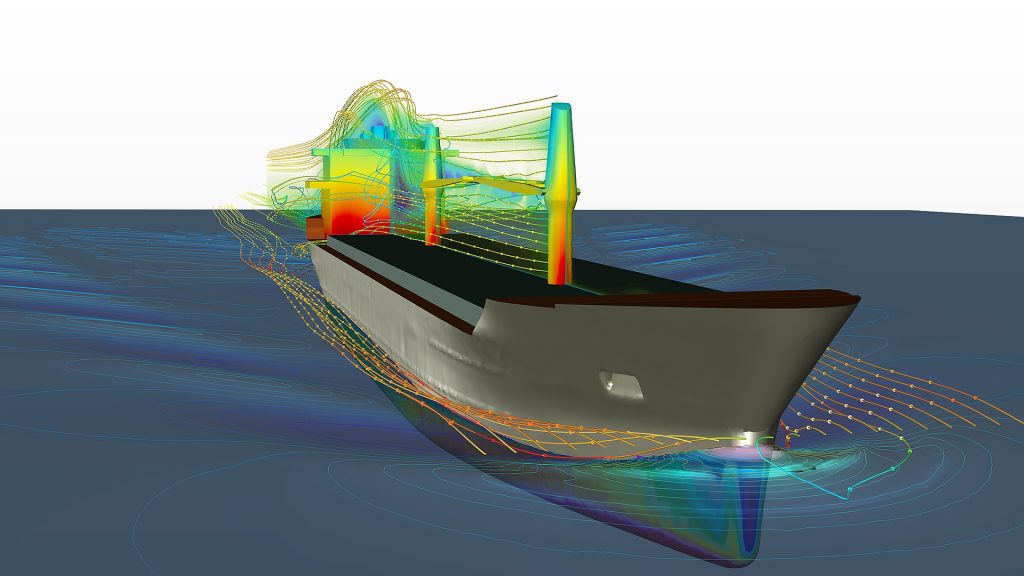

Simulation Dynamics’s engineers also use shape-optimization methods to improve heat transfer for given problem conditions. For fatigue assessment we use Simulia FE-SAFE, Ansys nCode DesignLife and FEMFAT to calculate different types of fatigue safety factors from the results of thermo-mechanical simulations. The new design delivers the long life and high quality Simulation Dynamics’s customers expect.

-

▶

Multimaterial thermal/structural coupling via CFD → FEA transfer

-

▶

One-way vs two-way FSI: when to update mesh and flow

-

▶

Fatigue & life prediction with FE-SAFE, nCode DesignLife, FEMFAT